Your search for the best fat splitting plant for making fatty acids and monoglycerides useful in many industries ends here. The significant reason is the best plants produced by the top manufacturer will perform the hydrolysis reactions at high temperatures and pressure of the vegetable oils. It enables the harmful triglycerides to react with water to convert into fatty acids and glycerol.

The fatty acid, being a lipid compound, plays a pivotal role in the human diet, cosmetics, plastics, lubricants, plastics, resin, coatings, etc. Monoglyceride or glyceride is a natural emulsifier that has wide functions in the food industry, pharmaceuticals, antioxidants, antibacterial, cosmetics, etc. So the fat splitting process is a crucial step for vegetable oils done by the best plants made by experienced manufacturers. Also, plants produce hydrogenated fats for increasing stability, texture, mouthfeel, shelf life, and others. ,

So, let us check out the many tips to choose the best fat splitting plant to enable the production of high-quality fatty acids and glycerides from vegetable oils to develop the business to new heights.

Six tips for choosing the best fat splitting plant

The triglycerides in the vegetable oils get split into fatty acids and glycerides by undergoing the fat-splitting process. But to make the fatty acids and glycerides with high quality to be useful in many sectors, the best fat splitting plant is caused by an expert manufacturer. But with many manufacturers making them, the following tips will help you choose the best fat-splitting plant.

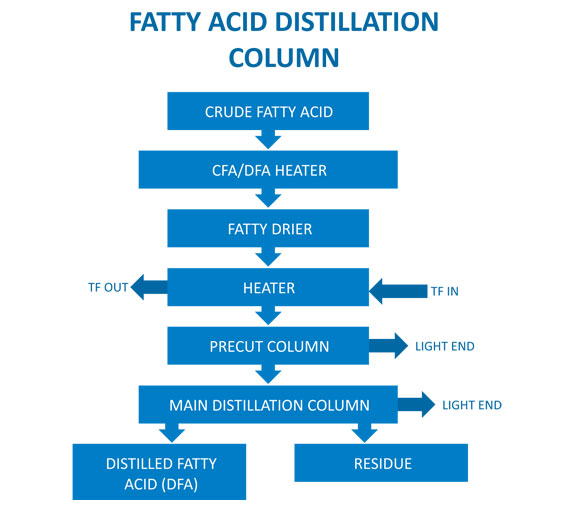

Check if the plant has a high-pressure single tower system to pre-heat the fatty matter to feed to the de-aerator for operating under a vacuum.

Confirm if there is an efficient heat recovery section for heating the de-aerated heat fed through the high-pressure pump with sweet water.

Verify if the high-pressure splitting tower has temperature controllers for heating the processed water discharged from crude fatty acids.

Check if the plant has the pre-cut column that enables the system to handle even the worst possible feedback, like acid oils, PFAD, etc, to produce high-grade distilled soap noodles and fatty acids.

Confirm if the plant optimizes the heat recovery to produce 3 bar steam for reducing the thermal stress on the final product by using falling film evaporators.

Verify if the plant has a structured packed column for efficient distillation to separate colors, odors, and fractions to make the product edible and pleasant.

The above facts and tips will help you choose Mectech, which has been making the best plants for hydrogenated fats for the past four decades and does the fat splitting process for cost-effective production of large quantities of fatty acids and glycerides with consistent quality, versatility, sustainability, and other for use in many sectors.