Composite rollers are innovative components used in different industries for material handling and conveyor systems. Unlike traditional metal rollers, composite rollers are constructed using a combination of materials such as high-density plastics, fiberglass, and other reinforced polymers. This unique composition delivers different benefits including developed durability, resistance to corrosion, and chemicals, and decreased weight. The usage of composite rollers is specifically beneficial in corrosive environments, as they do not trust or degrade over time. Their lightweight nature contributes to energy effectiveness and decreases the overall power demanded for conveyor systems. Moreover, composite rollers exhibit excellent shock absorption, decreasing wear and tear on both the rollers and conveyed materials.

These rollers find applications in different segments such as manufacturing, mining, and logistics, where they contribute to smoother and more reliable material transport. The increasing adoption of composite rollers reflects their positive impact on functional effectiveness and longevity in different industrial settings.

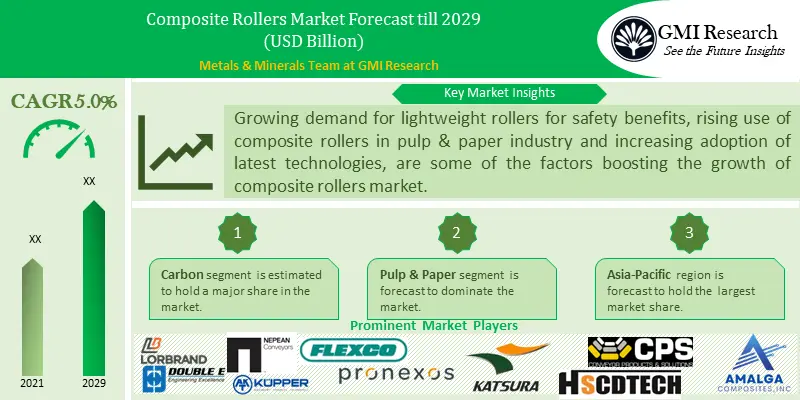

Composite Rollers Market Market Size

According to GMI Research, the global composite rollers market is predicted to register a CAGR of 5.0% in the forecast period, till 2029 attributed to an increase in the need for lightweight rollers around the globe.

Benefits of Composite Rollers

Composite rollers have attained prominence in the domain of material handling and conveyor systems, offering a multitude of benefits that contribute to improved functional effectiveness and longevity. One of the primary benefits deceits in their developed durability. Crafted from a combination of materials such as fiberglass and reinforced polymers, composite rollers exhibit notable resistance to corrosion, degradation, and wear. This durability translates to a prolonged lifespan, surpassing the longevity of traditional metal rollers.

The lightweight composition of composite rollers is another foremost benefit. This characteristic not only makes them easier to handle during installation but also leads to increased energy effectiveness in conveyor systems. The reduced weight lowers the power demands, resulting in cost savings and environmental benefits owing to decreased energy consumption.

Composite rollers excel in shock absorption a critical feature that decreases wear and tear on both the rollers and the materials being conveyed. This not only develops the complete lifespan of the rollers but also confirms the protection of transported goods, making them suitable for delicate or sensitive materials. Additionally, their resistance to corrosive environments is a distinctive benefit. Unlike metal rollers that may succumb to rust or chemical deterioration, composite rollers remain unaffected, making them an ideal option for industries where exposure to harsh substances is common.

Industries such as manufacturing, mining, and logistics benefit significantly from the implementation of composite rollers. The smoother and more reliable material transport they facilitate leads to increased functional effectiveness. In addition, the durability of composite rollers decreases maintenance costs, making them a cost-effective and sustainable solution for different industrial applications.

The benefits of composite rollers encompass developed durability, decreased weight for energy effectiveness, excellent shock absorption, and resilience in corrosive surroundings. These benefits position the composite rollers market as a profitable and valuable industry.

Applications of Composite Rollers

Composite Rollers find versatile applications across the spectrum of industries, revolutionizing material handling and conveyor systems. Their unique composition, often combining materials such as fiberglass, and reinforced polymers, makes them well-suited for different demanding environments.

In mining operations, composite rollers play an important role in transporting bulk materials efficiently. Their resistance to wear and corrosion makes them ideal for handling abrasive substances commonly encountered in mining procedures. The lightweight nature of composite rollers also contributors to energy saving, crucial in large-scale mining functions.

Manufacturing facilities benefit from the durability and resilience of composite rollers in conveyor systems. These rollers withstand the rigors of industrial procedures, offering a reliable and long-lasting solution for moving raw materials and finished products along assembly lines. Their resistance to corrosion is specifically benefitted in environments where exposure to chemicals is common.

Logistics and distribution centers leverage composite rollers for their exceptional performance in conveyor systems. The shock-absorbing capabilities of these rollers confirm the safe and secure transport of goods, decreasing the risk of damage during handling. The lightweight design contributes to functional effectiveness, optimizing material flow in complex distribution networks.

Composite rollers also prove invaluable in agricultural settings where they handle the movement of harvested crops and agricultural products. The resistance to corrosion is beneficial in farm environments where exposure to varying weather conditions and agricultural chemicals is unavoidable.

Airports and baggage handling systems utilize composite rollers for their durability and effectiveness. The ability to resist wear and corrosion confirms reliable performance, even in high-traffic environments. The lightweight design contributes to reduced energy consumption in conveyor systems, aligning with sustainability goals.

Final Words

Composite rollers have become integral components in different industries, including manufacturing, aviation, mining, agriculture, and logistics. Their durability, lightweight, and resistance to corrosion, design make them indispensable for optimizing material handling processes in different and demanding applications.